5 Things I Was Wrong About Video

Posted by jasonstone20

|

5 Things I Was Wrong About Video August 31, 2021 03:52AM |

Admin Registered: 2 years ago Posts: 499 |

|

Re: 5 Things I Was Wrong About Video January 24, 2022 09:11PM |

Registered: 2 years ago Posts: 36 |

About his first statement, that lower edge thickness does not translate to better edge retention cutting cardboard, I believe it can be true only if the edge is so thin that it can't sustain itself during the cutting, unless you are taking that thinnes to the extreme it's unlikely in normal use, saying that in general is blatantly unlogical in my opinion.

Very thin bte blades can easily cut cardboard, carpet, rope even when the sharpness is very, very low, because the higher cutting ability makes up for it.

Thicker bte blades, not so much.

Cliff documented this very well in a couple of his videos.

Very thin bte blades can easily cut cardboard, carpet, rope even when the sharpness is very, very low, because the higher cutting ability makes up for it.

Thicker bte blades, not so much.

Cliff documented this very well in a couple of his videos.

|

Re: 5 Things I Was Wrong About Video January 25, 2022 06:53AM |

Admin Registered: 2 years ago Posts: 499 |

Millscale,

I think it is just that increased cutting ability from bte thickness doesn't increase edge retention, as does a reduced angle in the micro-bevel, edge angle, and edge finish. It just makes the cut easier to make. I think someone did a video that they took two knives, both with the same edge angle and edge finish, and the only difference was bte thickness. Now I could be wrong about this, edge retention isn't my specialty, (if i even have one, lol. ). Maybe someone else can chime in here. Also, unfortunately, in the common knife community vs us knife knerds, edge retention has been the benchmark for knife performance, and steel choice was the way to increase edge retention. Thankfully Cliff Stamp showed this was not the way to do things, if you ask me.

). Maybe someone else can chime in here. Also, unfortunately, in the common knife community vs us knife knerds, edge retention has been the benchmark for knife performance, and steel choice was the way to increase edge retention. Thankfully Cliff Stamp showed this was not the way to do things, if you ask me.

Edited 1 time(s). Last edit at 01/25/2022 06:56AM by jasonstone20.

I think it is just that increased cutting ability from bte thickness doesn't increase edge retention, as does a reduced angle in the micro-bevel, edge angle, and edge finish. It just makes the cut easier to make. I think someone did a video that they took two knives, both with the same edge angle and edge finish, and the only difference was bte thickness. Now I could be wrong about this, edge retention isn't my specialty, (if i even have one, lol.

). Maybe someone else can chime in here. Also, unfortunately, in the common knife community vs us knife knerds, edge retention has been the benchmark for knife performance, and steel choice was the way to increase edge retention. Thankfully Cliff Stamp showed this was not the way to do things, if you ask me.

). Maybe someone else can chime in here. Also, unfortunately, in the common knife community vs us knife knerds, edge retention has been the benchmark for knife performance, and steel choice was the way to increase edge retention. Thankfully Cliff Stamp showed this was not the way to do things, if you ask me.Edited 1 time(s). Last edit at 01/25/2022 06:56AM by jasonstone20.

|

Re: 5 Things I Was Wrong About Video January 25, 2022 06:08PM |

Admin Registered: 2 years ago Posts: 147 |

Edge Retention from edge angle

the fact that lower edge angles increase edge retention is undeniable, and proven science, that is not in question and has not been for a very long time, no matter how many people want to do some small test that doesn't work well for them in a particular condition

this will always apply, and it will apply until you start creating edge angles that are too thin for the apex to stay stable, which is a high focus of Roman Landes work.

it is also very clearly shown that if you have a knife steel that is stable at 15dps, but is not stable at 6dps, that you can still improve its abilities by grinding it 6dps with a true micro bevel of 15dps.. we are talking a bevel that is only 20-30 microns to stabilize the apex. on the same knive this will be better than a full 15dps because it reduces the load on the edge in harder materials.

the fact that lower edge angles increase edge retention is undeniable, and proven science, that is not in question and has not been for a very long time, no matter how many people want to do some small test that doesn't work well for them in a particular condition

Quote

Larrin

You can see that the initial cut length with a smaller angle is considerably higher and that the difference holds basically to the end of the test. This finding is significant because some have speculated that lower angle edges start out sharper but a more obtuse edge lasts longer [2]. And with the high wear that occurs in the CATRA test it isn’t likely that the situation would reverse with even further cutting. The initial blunting rate is relatively rapid regardless of angle and it then begins to level out. The highest TCC measured was over 1000 mm with an angle of 20°, and this decreased all the way to under 100 mm with 56°. In a CATRA study by Bohler-Uddeholm [3] with a range of steels, but unspecified edge geometry or sharpening, 154CM was measured at 547 mm, and M390 was measured at 959 mm. The 547 mm value would be with an edge angle around 30° in this study if other parameters are similar. So if the edge angle of a 154CM knife is reduced from 30° to 20° then it can match or exceed a steel with 75% greater wear resistance.

this will always apply, and it will apply until you start creating edge angles that are too thin for the apex to stay stable, which is a high focus of Roman Landes work.

it is also very clearly shown that if you have a knife steel that is stable at 15dps, but is not stable at 6dps, that you can still improve its abilities by grinding it 6dps with a true micro bevel of 15dps.. we are talking a bevel that is only 20-30 microns to stabilize the apex. on the same knive this will be better than a full 15dps because it reduces the load on the edge in harder materials.

|

Re: 5 Things I Was Wrong About Video January 25, 2022 07:31PM |

Admin Registered: 2 years ago Posts: 499 |

|

Re: 5 Things I Was Wrong About Video January 25, 2022 07:33PM |

Registered: 2 years ago Posts: 256 |

The last point about holding the blade at the cryogenic temperature for longer not doing anything was kinda odd because he referenced the HRC number as evidence that it doesn’t do anything meaningful. Well the HRC number isn’t the point anyway, the point of cryogenic quenching is to lower the percentage of RA, not to gain Rockwell points. Now offhand I’m not sure what difference would actually occur from different hold times, but either way he’s not understanding the point of the quenching.

|

Re: 5 Things I Was Wrong About Video January 25, 2022 10:56PM |

Registered: 2 years ago Posts: 36 |

I agree that edge retention can be influenced by the wear resistance of the alloy, regardless of the edge thickness, but shouldn't the higher cutting ability and the lower forces applied lower the amount of stress on the very apex, decreasing damage anyway? I don't know, maybe someone will enlighten us.

Onestly I've never been a fan of super-high carbide steel, I believe ease of grinding for a knife is a much better feature than higher carbide content, especially since this generally implies lower toughness, tendency to chip,, coarser grain structure, stubborn burring, thicker edges at higher angles to reach stability and so on.

Seems odd.

Onestly I've never been a fan of super-high carbide steel, I believe ease of grinding for a knife is a much better feature than higher carbide content, especially since this generally implies lower toughness, tendency to chip,, coarser grain structure, stubborn burring, thicker edges at higher angles to reach stability and so on.

Seems odd.

|

Re: 5 Things I Was Wrong About Video January 25, 2022 11:17PM |

Registered: 2 years ago Posts: 36 |

"Thinner edges, regardless of final edge angle, did have a small advantage in edge retention [...] This is consistent with previous studies using a fixed angle but different edge thickness"

Apparently it has some effect, but non comparable to edge angle.

Thank you cKc for the link, I will read the article better tomorrow.

Apparently it has some effect, but non comparable to edge angle.

Thank you cKc for the link, I will read the article better tomorrow.

|

Re: 5 Things I Was Wrong About Video January 26, 2022 12:29AM |

Admin Registered: 2 years ago Posts: 499 |

Quote

Millscale

I agree that edge retention can be influenced by the wear resistance of the alloy, regardless of the edge thickness, but shouldn't the higher cutting ability and the lower forces applied lower the amount of stress on the very apex, decreasing damage anyway?

That is what I originally thought also, but when I asked around to people I got an answer that said no it didn't to any significance.

Edited 1 time(s). Last edit at 01/26/2022 12:30AM by jasonstone20.

|

Re: 5 Things I Was Wrong About Video January 26, 2022 01:14AM |

Admin Registered: 2 years ago Posts: 147 |

Quote

jasonstone20

cKc,

How does BTE thickness effect edge retention? That is what we are trying to figure out.

by itself BTE isn't easy to identify as a reason.

rather than worrying specifically about the bte, its more a case of thinking how much force is required to make one object penetrate another.

the moment the apex makes contact with the material cut, you are starting to apply a force against it the more obtuse the edge is, the more resistance it will have to getting into the material, which means you have to push harder. the harder you are pushing, the more force is being pushed back on that tiny apex.

BTE is relevant if you are only talking about a secondary bevel without micro bevels, but it doesn't matter if you have a knife 15dps 0.020 bte or 15dps 0.1" bte.. all this means is that the bevel is longer. bte is only a relevant number when talking about distance from the apex as a means of calculating the approximate edge angle if not known. the relevant area is the actual apex which is tiny.

the main things to think of is that if you have a 12dps edge like a scandi, then it is getting thicker and thicker as a support structure. if something is going to fail, its going to fail at the apex, because it is the weakest point..

but if you do something like make a 25dps edge that is only 0.01" which immediately converts to a nice deep hollow grind then rather than the damage occurring just at the apex, it will more likely buckle the steel behind the BTE if you need more force than the apex can handle.

if you recall on the old forum, i built a spreadsheet and video to demonstrate the effect of edge angle changes on the strength of a knife via its thickness.

you want the knife edge to be just thick enough, and not too thick. if the material you are cutting is resistant enough to penetration that the edge angle itself is preventing it to go in, then it will damage quickly..

the most simple example is a pin or needle. when it is sharp, its easy to go into leather etc. but the moment you get dulling or a needle too thick for the job, it wont go in, and it will bend the pin, or fold the apex instead

|

Re: 5 Things I Was Wrong About Video January 26, 2022 01:25AM |

Admin Registered: 2 years ago Posts: 147 |

Quote

Ryan Nafe

The last point about holding the blade at the cryogenic temperature for longer not doing anything was kinda odd because he referenced the HRC number as evidence that it doesn’t do anything meaningful. Well the HRC number isn’t the point anyway, the point of cryogenic quenching is to lower the percentage of RA, not to gain Rockwell points. Now offhand I’m not sure what difference would actually occur from different hold times, but either way he’s not understanding the point of the quenching.

this depends on the steel to a degree, but in general its correct that cryo only needs to reach the temperature, and not hold the temperature.

the cryo is converting retained austentite into martensite as an act of dropping to that temp. once it is done, holding it wont convert more.

there are different ways to get there, and i wonder what effect they have. there are those that dip them into chambers. some dip them directly into nitro which i think is way too much shock and risks cracking.

my heat treater would put them in a chamber and then drop the temperature over the coarse of an hour. hold for a few minutes to let all the steet soak, then draw the temperature back down slowly so that no shock occurring. better or not i dont know.

we also used snap tempers, or full tempers depending on the steel, to reduce cracking risks, which reduced the ultimate hardness, but still garnered 62rc which was more than adequate for my needs

cryo from larrin

|

Re: 5 Things I Was Wrong About Video January 26, 2022 07:24PM |

Admin Registered: 2 years ago Posts: 499 |

I found Cliff's original post about how he modeled Cutting Ability:

[www.bladeforums.com]

Edited 1 time(s). Last edit at 01/27/2022 07:13PM by jasonstone20.

[www.bladeforums.com]

Quote

https://www.bladeforums.com/threads/a-model-for-cutting-ability.421313/

Recently I proposed how to model edge retention and showed a few examples of it in use :

[www.bladeforums.com]

[www.bladeforums.com]

Now for a harder question, can you model cutting ability? Under a specific amount of force can you predict how deep a blade cuts and how this changes with repeated cuts? Can you model this :

chart2.gif

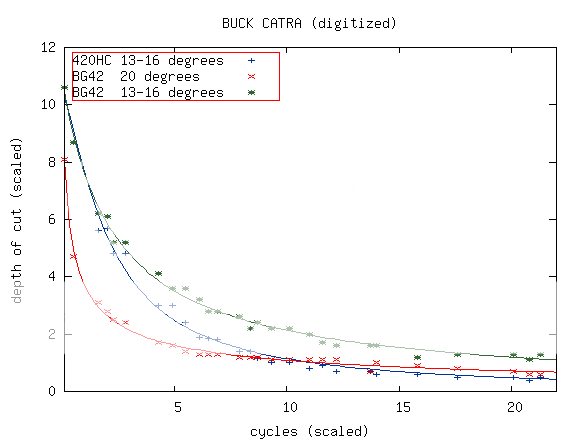

These are CATRA tests done by Buck knives to promote the Edge 2000 sharpening method. Buck reduced the angles from 35-50 degrees included to 26-32 degrees included and switched to a harder sharpening medium and thus removed the convexing of the cloth wheels. This work (2001) showed blades which cut better initially but cut better for longer. The effect of geometry was so significant that a 420HC blade with the flatter and more acute edge outcut both a ATS-34 and BG-42 blade with the older thicker convex edges. Now if you also re-profiled the BG-42/ATS-34 blades they would of course outperform the 420HC blade as shown here :

chart1.gif

Now this had been known for years to those active on rec.knives and I had discussed it in detail in many reviews showing how changing the angle and as well the grit had the same effect. This was based on work by Swaim and Talmadge. Swaim had been doing it for years when I entered the discussions (lurking) in 1998. Now as to the model - cutting ability is basically inversely proportional to the force on the blade. Now ignoring friction (which is usually valid for several reasons) the force on a blade due to wedging is just a constant determined by the cross section which doesn't change during the cutting plus the force against the very edge which is essentially the bluntness which I have modeled before. Thus the cutting ability is then :

Code:

CA(x)=CA_0/(1+b*x^c)

Where CA(x) is the cutting ability after a given amount of cuts in the test medium (x). CA_0 is the initial cutting ability with no blunting, which is a function of the stiffness of the media and the shape of the blade and initial sharpness. The constants b and c relate how and at what rate the blade blunts. These are the same coefficients as noted in the above linked posts as that part of the equation is of course the equation which I previously used to model sharpness. Ok, now does it work :

buck_catra_bg_420HC.png

Those points are data digitized from the CATRA graphs which is why the axis are scaled (yes I could scale it back, there just isn't any point). The model replicates both early and late stage cutting ability. As noted eariler, Swaim predicted this behavior back in 1998 where he first noted his opposition of greater angles=better edge retention, one of many myths which still persist. I'll be using this model shortly to discuss the hemp cutting and other work I have done. I wanted to use a CATRA model first as it is completely independent data. I will also be using examples of other similar tools, like dental scrapers and such just to show the more general implications. Note I didn't quote the numbers that come out of the model in the above because I didn't have the raw data. I will have all of this for the data I have collected so I'll discuss some of the issues in more detail when I use that.

As a side note, the CATRA curves also show the self-sharpening effect which I first noted in late 1999 during work with Boye blades. The sharpness can decrease then rebound as the edge chips, wears smooth, and this pattern repeats. I had been meaning to look at these curves in more detail for awhile but got distracted with other work. Note in the above I modeled the force in a simple manner :

F_w+F_e

Or force due to wedging (F_w) plus force on the edge (F_e), you can actually break this up and model the force due to wedging in components and thus separate the effect of edge angle and thickness. You can also use this model to do something like compare the edge retention of two blades at different geometries because it is a multi-variable model which includes both geometrical and steel properties. Thus for example you could model the effect of different steels and geometries and thus predict how they would act at different angles or finishes. With a decent spread of steels over different properties (hardness, wear resistance, carbide size) you could also predict the exact properties needed in a steel to give the desired cutting abilities.

Once you have these two coefficients you can also calculate the ratio F_e/F_w which then tells you the fractional dependence of the edge retention on the cutting lifetime. This for example is very high for hemp but very low for soft woods. This shows that you can cut soft wood very well with a blunt blade because most of the force is due to wedging, but trying to cut hemp rope with a dull blade isn't productive. This is why for example makers trying hype blades will do something like cut up a coffee can and then slice wood showing the "superior" edge retention of the knife. In fact because the F_e/F_w ratio is so low for that media the test is nothing but hype. So as a side note, this also lets you quantify hype.

-Cliff

Edited 1 time(s). Last edit at 01/27/2022 07:13PM by jasonstone20.

|

Re: 5 Things I Was Wrong About Video January 26, 2022 07:33PM |

Admin Registered: 2 years ago Posts: 499 |

I really would like to add this Cutting Ability formula to my and ShaperAndMowers Knife Angle/Edge Retention/Steel Table JavaScript program:

V-Stick Angle

V-Stick Angle

|

Re: 5 Things I Was Wrong About Video January 26, 2022 08:38PM |

Registered: 2 years ago Posts: 256 |

Quote

cKc (Kyley Harris)

this depends on the steel to a degree, but in general its correct that cryo only needs to reach the temperature, and not hold the temperature.

the cryo is converting retained austentite into martensite as an act of dropping to that temp. once it is done, holding it wont convert more.

I missed the distinction between holding it there and just getting it there. Getting it there is what I was thinking of. I haven’t read anything on extended times but I’ve seen quite a lot on the effects of the cryogenic quenching itself.

On a similar note, I found out that I once again have access to a Rockwell C scale hardness testing machine. Some of you may remember the thread I made 3 or 4 years ago on the subject. I’ll make a new thread on that subject when I start testing knives again and annotate it with the numbers found on previous knives in the old thread. First one up for testing is the SPY27 steel Native 5. Second knife for the testing will be the Benchmade S90V hunting knife that should be arriving in the mail today.

|

Re: 5 Things I Was Wrong About Video January 27, 2022 02:40AM |

Admin Registered: 2 years ago Posts: 147 |

Quote

Ryan Nafe

this depends on the steel to a degree, but in general its correct that cryo only needs to reach the temperature, and not hold the temperature.

the cryo is converting retained austentite into martensite as an act of dropping to that temp. once it is done, holding it wont convert more.

I missed the distinction between holding it there and just getting it there. Getting it there is what I was thinking of. I haven’t read anything on extended times but I’ve seen quite a lot on the effects of the cryogenic quenching itself.

On a similar note, I found out that I once again have access to a Rockwell C scale hardness testing machine. Some of you may remember the thread I made 3 or 4 years ago on the subject. I’ll make a new thread on that subject when I start testing knives again and annotate it with the numbers found on previous knives in the old thread. First one up for testing is the SPY27 steel Native 5. Second knife for the testing will be the Benchmade S90V hunting knife that should be arriving in the mail today.

a lot of people have been testing spyderco. from what i have heard, they tend to always be withing the +/- range which is good.

in regards to s90v.. note that if it is a coated blade, you need to remove the coating to perform an accurate test.

|

Re: 5 Things I Was Wrong About Video January 27, 2022 03:05AM |

Registered: 2 years ago Posts: 256 |

Quote

cKc (Kyley Harris)

in regards to s90v.. note that if it is a coated blade, you need to remove the coating to perform an accurate test.

Yeah that’s actually the reason I’ve been trying to get blades that aren’t coated, where possible. In one case I found a very coarse bead blast seemed to effect the blade. The edge behaved as I would expect D2 at about 60 to behave, it was difficult to grind but took a high sharpness without major burr formation, but tests were showing much lower hardness than that. It was either differentially hardened or the bead blast was messing the test up, I couldn’t figure out which one it was.

The S90V knife I ordered is this one, I’ll make some careful examinations of the factory edge to see what the “Select Edge” thing really is:

[www.benchmade.com]

The stock thickness is reasonable at .120”, they claim to put a 14 DPS edge on it, and in pictures the edge bevel doesn’t look very wide so I suspect that the edge isn’t overly thick, either. The slight recurve might be a problem though, it might make it hard to apex it cleanly on a diamond plate.

|

Re: 5 Things I Was Wrong About Video January 27, 2022 07:08PM |

Admin Registered: 2 years ago Posts: 499 |

[www.bladeforums.com]

Notice this was posted in 2006, a little before BladeForums permanently banned Cliff.

Edited 1 time(s). Last edit at 01/27/2022 07:10PM by jasonstone20.

Quote

Cliff Stamp

es, I watched a program on discovery awhile back in which it showed how the basic axe progressed as the metals got harder and stronger and allowed a refinement of the taper from the crude heavy convex bevels of the softer metals to the very strong steel alloys and the very flat and thin bevels. So the basic idea to minimize cross section is a very old one.

Unfortunately on the forums the discussions were often lead by the people selling the knives and thus steel was the focus and the idea that knives cut due to steels was a major point and you often saw argued things like forging improving cutting ability. Some of this still exists now where you will hear forged blades have "better balance" and similar.

Swaim was one of the first guys to stand up and say that was all wrong. Look at the shape of the knife to see how it will perform. How is it ground, what is the weight, where is it balanced. He also discussed both the center of mass and the impact node, noting for example a Cold Steel khukuri was inferior to a Ontario machete because the khukuri had too shallow an impact zone which had too much vibration, especially towards the tip.

Lee's book on sharpening discusses many similar issues, noting the use of very thin bevels, coarser grits for slicing and it predates the discussions on rec.knives by several years. I doubt Lee would claim he invented much of the practices either.

Notice this was posted in 2006, a little before BladeForums permanently banned Cliff.

Edited 1 time(s). Last edit at 01/27/2022 07:10PM by jasonstone20.

|

Re: 5 Things I Was Wrong About Video January 27, 2022 07:15PM |

Admin Registered: 2 years ago Posts: 499 |

|

Re: 5 Things I Was Wrong About Video January 27, 2022 07:30PM |

Registered: 2 years ago Posts: 256 |

Quote

Ryan Nafe

The slight recurve might be a problem though, it might make it hard to apex it cleanly on a diamond plate.

There actually isn’t a recurve in the edge, it’s an optical illusion. The section of edge nearest the handle is actually straight, it just slants upward at an angle.

The knife I got looks like a store display model: the edge is impacted in several places, it’s obvious that the knife has been taken in and out of the sheath several times already (cuts to the boltaron), and there’s a sticker on the blade. Being that I paid full price and that that one wasn’t the last one in stock per the seller’s website, I may return it. But I’m not sure yet, it would be a hassle and their storefront is almost an hour away from me.

The good news is that the edge is indeed ground at about 13 to 15 DPS, and the edge is 0.020” thick. So the cutting performance should be pretty decent and the blade/edge shape, blade steel, and a coarse finish like a DMT Fine or Coarse should all work nicely together to make the knife cut with a draw for a very long time. It also got face-shaving sharp with just a few passes at 20 DPS on my DMT plate. It does indeed look like a very solid platform for testing S90V in all sorts of ways.

|

Re: 5 Things I Was Wrong About Video January 27, 2022 08:18PM |

Registered: 2 years ago Posts: 256 |

|

Re: 5 Things I Was Wrong About Video January 27, 2022 10:57PM |

Admin Registered: 2 years ago Posts: 499 |

Ryan,

Sucks that it came in that condition. Maybe you can get a partial refund or a discount on another purchase. I haven't really played with S90V a lot, I had a loner for a little while. I do have a knife in M390, which is suppose to have a similar carbide content to S90V. My experience with high carbide steels has been good, they are great for cardboard cutting.

Sucks that it came in that condition. Maybe you can get a partial refund or a discount on another purchase. I haven't really played with S90V a lot, I had a loner for a little while. I do have a knife in M390, which is suppose to have a similar carbide content to S90V. My experience with high carbide steels has been good, they are great for cardboard cutting.

|

Re: 5 Things I Was Wrong About Video January 28, 2022 12:10AM |

Admin Registered: 2 years ago Posts: 499 |

Quote

Millscale

I agree that edge retention can be influenced by the wear resistance of the alloy, regardless of the edge thickness, but shouldn't the higher cutting ability and the lower forces applied lower the amount of stress on the very apex, decreasing damage anyway? I don't know, maybe someone will enlighten us.

Onestly I've never been a fan of super-high carbide steel, I believe ease of grinding for a knife is a much better feature than higher carbide content, especially since this generally implies lower toughness, tendency to chip,, coarser grain structure, stubborn burring, thicker edges at higher angles to reach stability and so on.

Seems odd.

Millscale,

Cliff explains why it doesn't really have an effect on edge retention, while it does have on cutting ability:

Quote

Cliff Stamp

From first inspection this seems reasonable because a more acute edge angle, again we are talking about the part which does the cutting here, not the part which is behind it, should be easier to wear, fracture and deform. Swaim however countered this arguement on rec.knives with the proposal with two contentions. First off all, if the angle is lower it actually takes more steel to be removed to get to a given thickness and second the forces on an edge are lower due to the higher cutting ability as edge angles are reduced. Thus he proposed it isn't necessarily true that if you grind an edge at 15 degrees that the cutting ability will decrease quickly below the knife sharpened at 20 degrees. Again, there is no mention of relief grinds, this is an issue of the angle at the edge itself. Now I had much data collected which supports Swaims hypothesis but there are always people who as Cashen is fond of noting :

And honestly this refreshes my memory of my conversation with Cliff on why it effects cutting ability and not edge retention, is because only a very small part of the edge, 20-40u, is actually doing the cutting, ie hitting the material being cut. Anything behind that has a very small effect as far as it comes to the edge retention, the BTE thickness reduction is mostly reducing friction. Like I said before, I asked Cliff the exact same question about CA and Edge Retention. I just couldn't remember why it was the case. In that old thread on BladeForums, there is a lot of good stuff there, and it really explains things. There are 4 pages of it.

Sorry, only registered users may post in this forum.