What can AEB-L handle in geometry

Posted by cKc (Kyley Harris)

|

What can AEB-L handle in geometry February 13, 2022 11:19AM |

Admin Registered: 2 years ago Posts: 147 |

Starting this thread to move from another thread, to show examples and discuss AEBL geometry.

I will make a new post per example and edit as required

this is a nice example of a kitchen knife in AEBL

I ended up sending this one to Cliff for testing, so i can use his measurements as recorded in the old forum

old forum

-62RC AEBL

-2.5mm at the thickest point

-190 grams

-9" edge

-the edge is 0.002-0.004" thick (tip to heel)

-1.3" high primary grind, very slight convex

I will make a new post per example and edit as required

this is a nice example of a kitchen knife in AEBL

I ended up sending this one to Cliff for testing, so i can use his measurements as recorded in the old forum

old forum

-62RC AEBL

-2.5mm at the thickest point

-190 grams

-9" edge

-the edge is 0.002-0.004" thick (tip to heel)

-1.3" high primary grind, very slight convex

|

Re: What can AEB-L handle in geometry February 13, 2022 11:24AM |

Admin Registered: 2 years ago Posts: 147 |

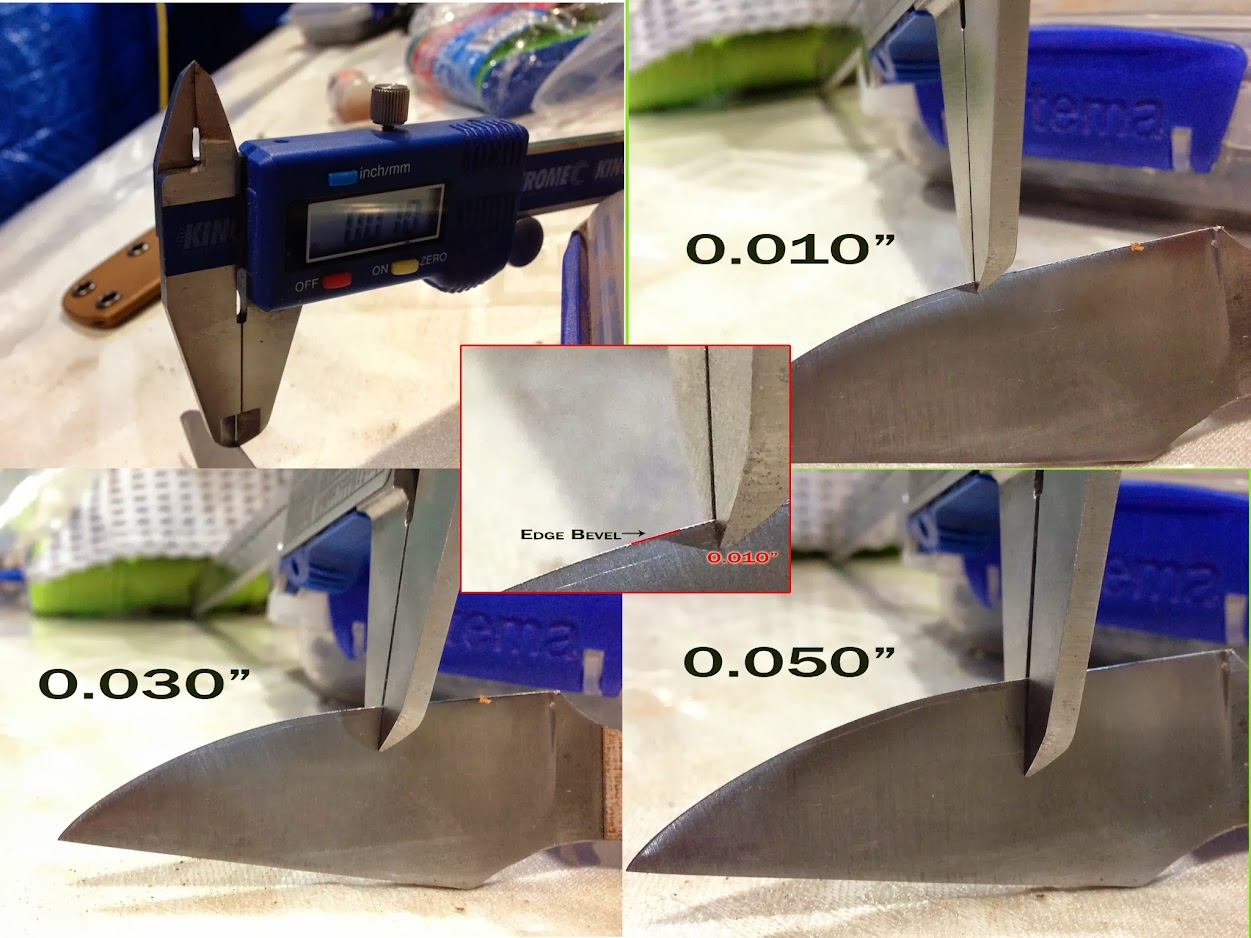

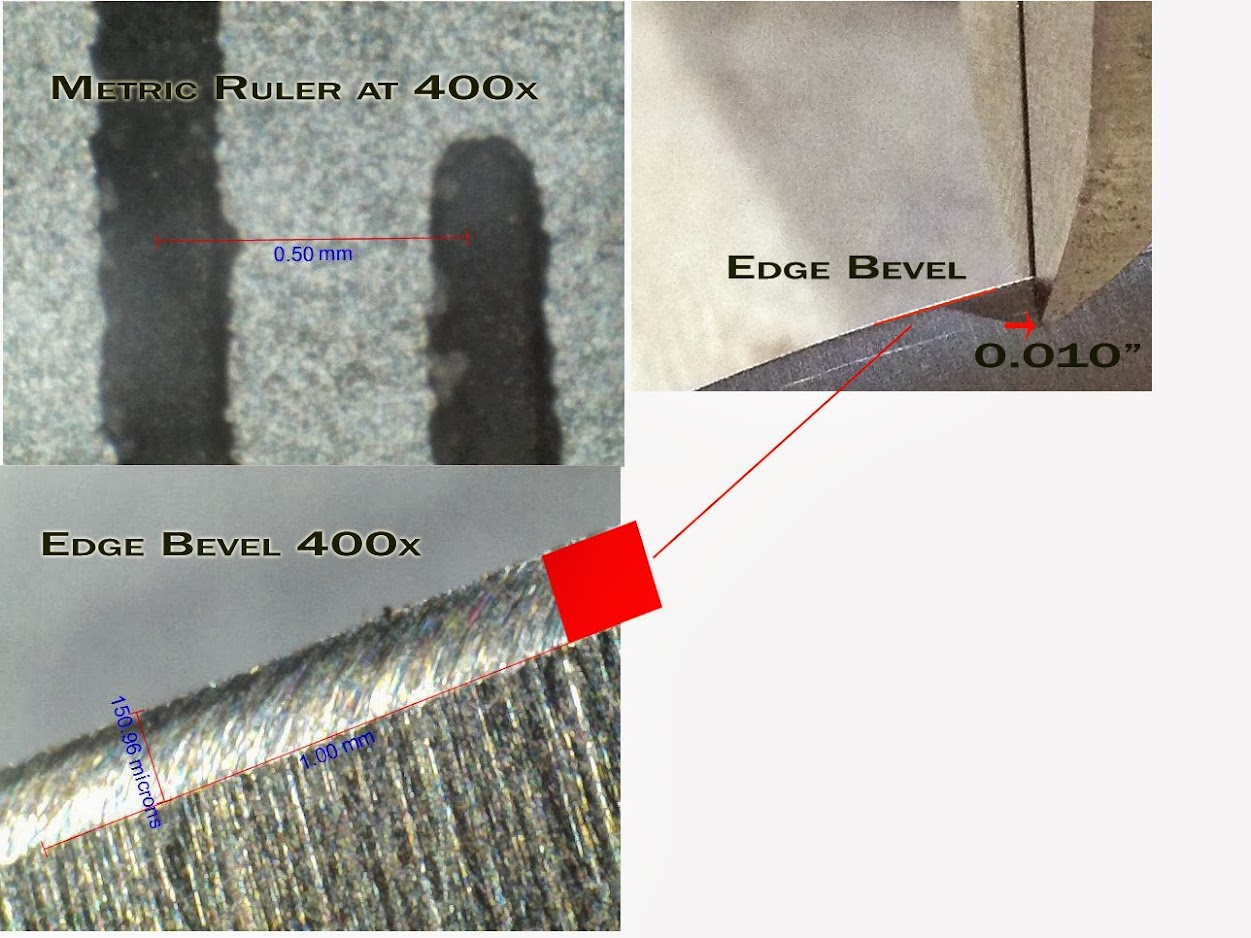

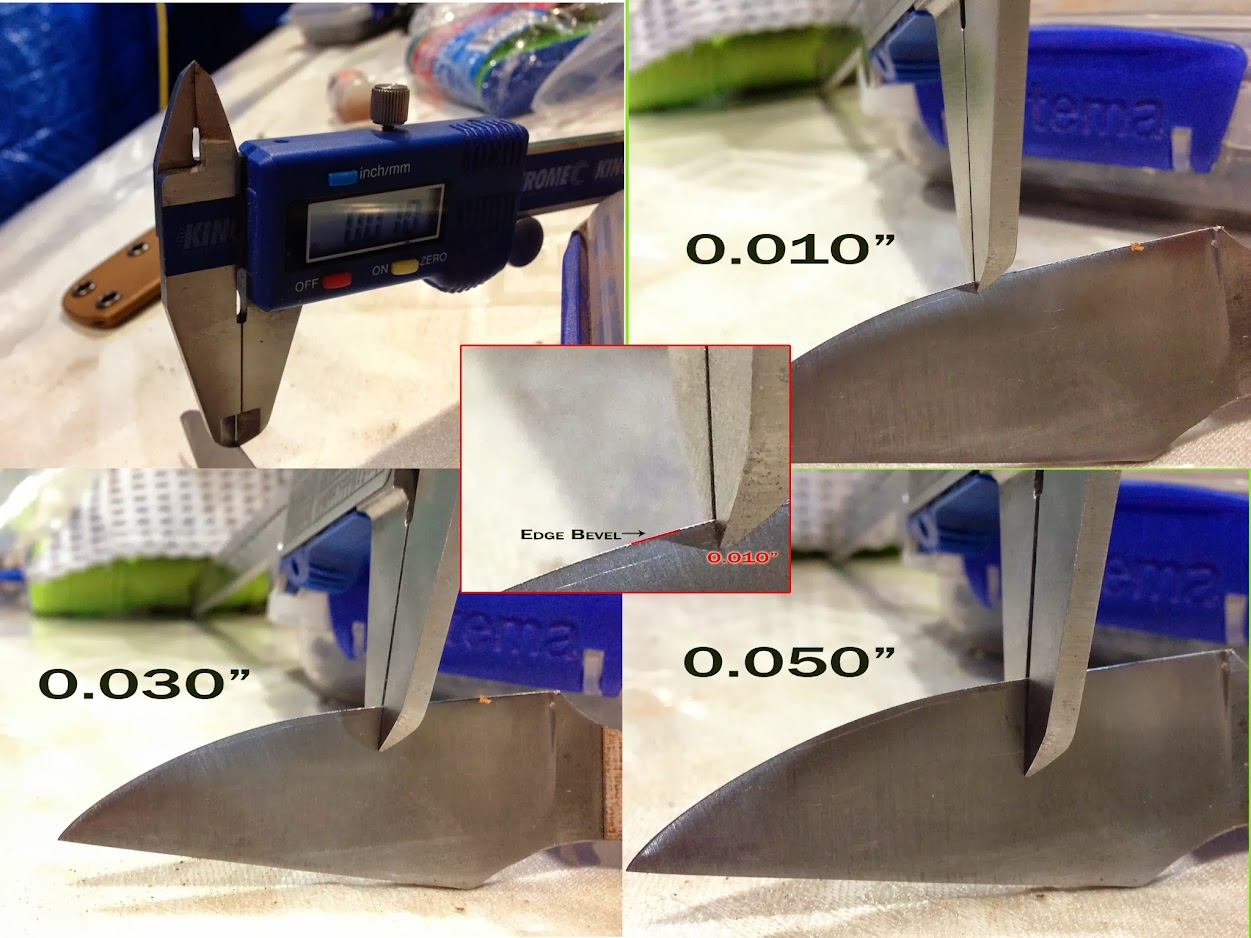

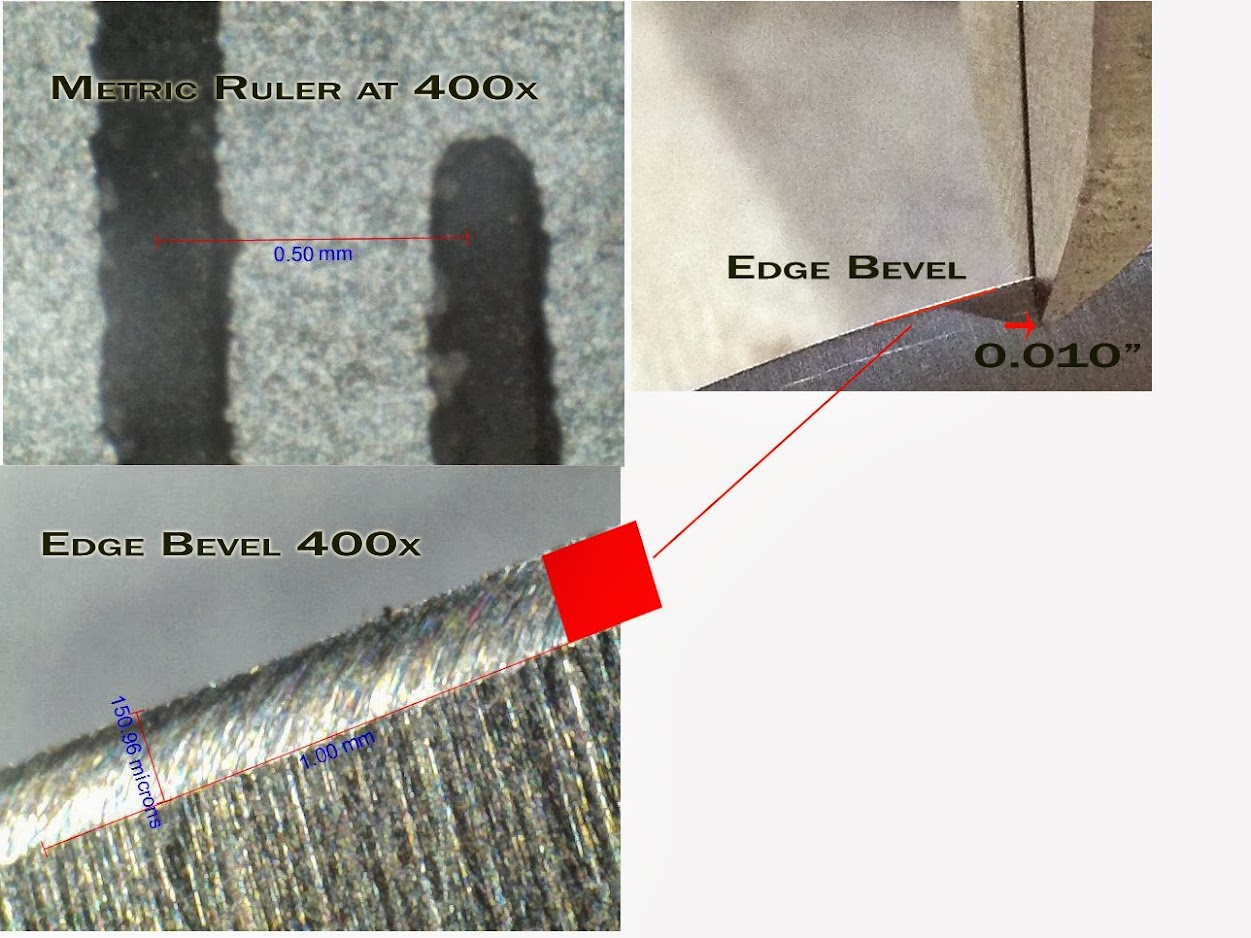

This is an example of my micro hikers. i did many different grinds on this depending on uses.. from anything like an 8dps scandi grind for shucking mussels to grinds like this one for utility. on avg most were ground to about 0.005" with edges in the 10-12dps range

these images dont quite fit, but you can open them from the attached links

the edge bevel on this would be between 10-14dps and no more than 0.003"

this video is showing the thinness of one that was ground to zero and a 0.001 micro bevel added.

scrape testing and apex examination at that thinness

discussion on old forum in regards to why i sent some of these knives to cliff to try and compare as i was getting damage on the apex that was unexpected. this was solved once i realized i'd never used laser cutting before vs Water jet, and i'd not removed the bad steel from the edge bevel.. once i cleaned up all the edges on my blanks the problem went away.

discussion on old forum

Edited 2 time(s). Last edit at 02/13/2022 11:38AM by cKc (Kyley Harris).

these images dont quite fit, but you can open them from the attached links

the edge bevel on this would be between 10-14dps and no more than 0.003"

this video is showing the thinness of one that was ground to zero and a 0.001 micro bevel added.

scrape testing and apex examination at that thinness

discussion on old forum in regards to why i sent some of these knives to cliff to try and compare as i was getting damage on the apex that was unexpected. this was solved once i realized i'd never used laser cutting before vs Water jet, and i'd not removed the bad steel from the edge bevel.. once i cleaned up all the edges on my blanks the problem went away.

discussion on old forum

Edited 2 time(s). Last edit at 02/13/2022 11:38AM by cKc (Kyley Harris).

|

Re: What can AEB-L handle in geometry February 13, 2022 11:54AM |

Admin Registered: 2 years ago Posts: 147 |

this is one of my 61 +/-1 rc hikers which are 2mm thick. this is no more than 0.005" on the edge, but the difference between a lot of my grinds and other peoples is that i dont just always do a flat grind to the spine no matter what making the knives always thinner than kitchen knives. i pick the heights of my grinds to give the knife thinner edges, with better support.

this blade is near flat with a subtle convex, so its more like 3dps - 4dps behind the cutting edge, but the edge itself is only 10-11dps. but unlike the other knife this one has enough meat in the edge that it wont ripple by pressing on it.. its a very durable blade even though thin.

This is very different from the standard full height blade were a zero grind even on a 1" height blade 0.1" thick is < 3dps.. the problem where the durability issues come from is going from a tiny 2-3dps to a 0.005" bevels of 15-18dps. the apex is too strong for the backing.

in terms of production.. an aebl knife 1" in height even if it was taken to 15-20 thousands and 15dps is very easy to gain similar performance to what i have here, because we only need to fix the BTE and apex.. not the entire blade.. so its the best of both worlds

|

Re: What can AEB-L handle in geometry February 13, 2022 10:43PM |

Registered: 2 years ago Posts: 11 |

Thanks for the write-up Kyley.

I've been thinking about this recently, as I have a batch of 0.070" at heat currently. My first utility knife I made in this thickness suffered the problem you described of having insufficient support of the primary and rippling readily as a result. It was ~0.002-0.003" with a 10dps edge initially, rippled when cutting diagonally into hardwood with firm pressure. I ground back to ~0.005" and it was fine until I notched a pine 2x4 across the end grain and the dense rings concentrated enough force to cause slight ripples.

I've been thinking about this recently, as I have a batch of 0.070" at heat currently. My first utility knife I made in this thickness suffered the problem you described of having insufficient support of the primary and rippling readily as a result. It was ~0.002-0.003" with a 10dps edge initially, rippled when cutting diagonally into hardwood with firm pressure. I ground back to ~0.005" and it was fine until I notched a pine 2x4 across the end grain and the dense rings concentrated enough force to cause slight ripples.

|

Re: What can AEB-L handle in geometry February 14, 2022 02:58AM |

Admin Registered: 2 years ago Posts: 147 |

Quote

Cowan

Thanks for the write-up Kyley.

I've been thinking about this recently, as I have a batch of 0.070" at heat currently. My first utility knife I made in this thickness suffered the problem you described of having insufficient support of the primary and rippling readily as a result. It was ~0.002-0.003" with a 10dps edge initially, rippled when cutting diagonally into hardwood with firm pressure. I ground back to ~0.005" and it was fine until I notched a pine 2x4 across the end grain and the dense rings concentrated enough force to cause slight ripples.

This is always where the balance of knowing what the knife will be used for ties in with the edge geometry. the question i would as is how thick was the knife behind the 0.003" or 0.005" if you are transitioning from 10dps to 3dps at 0.003 then you effectively have a razor blade, but if you are going from 0.003 into say 7-8dps for at least 0.2" length you are adding a lot of durablity

|

Re: What can AEB-L handle in geometry February 14, 2022 03:39PM |

Registered: 2 years ago Posts: 11 |

|

Re: What can AEB-L handle in geometry February 14, 2022 04:43PM |

Admin Registered: 2 years ago Posts: 147 |

Any thickening will have an impact. how negligible or not will be determined by the material being cut.

This is a video done by someone after they got one of my friction folders that is extremely thick. 5mm thick o1 steel around 20mm tall at the tallest,

and showing how the thinness at the apex makes a dramatic difference over some typical production knives.

that 01 knife if it was a zero grid from spine to apex would be 7DPS and you can't make it less.. that is the minimum possible angle. this just shows how solid 7dps really is when you let it go unfettered. the knife is a convex, so the actual apex is more like 10-11dps

it can be hard to see on camera, but i can tell you from my own experience that until you are used to always using knives where 13dps is what you call thick, its hard to explain how much resistance you feel if you use 15dps + on a knife for any hard cuts like hard rope, plastic, wood.

you can see and hear the shaking trying to get the folder in.

now, how far do you take that 6-7dps comes down to how durable you need the knife to be. the apex should be the lowest possible angle that wont get damaged. for me, unless it is extremely hard bone, or metals, 12dps is the max.

so you can see.. even taking 7/8 dps 20mm up a blade it can still perform very well, and far better than a much thinner knife with the wrong apex geometry. the key is to set an apex of a knife based on the type of material to bite into, and the spine thickness of a knife based on the resistance of material when following through.

if i was trying to do this test with the 5mm thick knife it would still do it, but that cut would be ripping the wood off the end. if trying to cut through the middle the 5mm knife would bind too much to get through. it would split the wood fibre instead of cutting.

this is why there is no perfect geometry.

the thinnest you can go without failing in what you want to do is the only answer.

Experimentation is the best way to find out what will happen. never take anything on faith

This is a video done by someone after they got one of my friction folders that is extremely thick. 5mm thick o1 steel around 20mm tall at the tallest,

and showing how the thinness at the apex makes a dramatic difference over some typical production knives.

that 01 knife if it was a zero grid from spine to apex would be 7DPS and you can't make it less.. that is the minimum possible angle. this just shows how solid 7dps really is when you let it go unfettered. the knife is a convex, so the actual apex is more like 10-11dps

it can be hard to see on camera, but i can tell you from my own experience that until you are used to always using knives where 13dps is what you call thick, its hard to explain how much resistance you feel if you use 15dps + on a knife for any hard cuts like hard rope, plastic, wood.

you can see and hear the shaking trying to get the folder in.

now, how far do you take that 6-7dps comes down to how durable you need the knife to be. the apex should be the lowest possible angle that wont get damaged. for me, unless it is extremely hard bone, or metals, 12dps is the max.

so you can see.. even taking 7/8 dps 20mm up a blade it can still perform very well, and far better than a much thinner knife with the wrong apex geometry. the key is to set an apex of a knife based on the type of material to bite into, and the spine thickness of a knife based on the resistance of material when following through.

if i was trying to do this test with the 5mm thick knife it would still do it, but that cut would be ripping the wood off the end. if trying to cut through the middle the 5mm knife would bind too much to get through. it would split the wood fibre instead of cutting.

this is why there is no perfect geometry.

the thinnest you can go without failing in what you want to do is the only answer.

Experimentation is the best way to find out what will happen. never take anything on faith

|

Re: What can AEB-L handle in geometry February 15, 2022 03:07AM |

Registered: 2 years ago Posts: 11 |

In the first video I find it interesting how well the convex splits the chip instead of wedging against it. I think that's likely a significant aid to penetration, given that you're pressing that wood up into space rather than trying to compress it.

I checked my knife and I think the spots that rolled the worst were the same ones that had rolled previously. I ground down the rolls from the side before I ground back into the bevel, so those spots were left slightly thinner. It's ~.005 bte at 10 degrees with a barely perceptible micro bevel of ~16 degrees, .010" at ~.125-.08 up the edge. I hadn't checked my sharpening geometry recently and it looks like I let it creep up to much. Can't say I'm surprised about the ripples at this point.

I re-profiled my edc by taking the shoulder off at ~6 degrees. It went from .010" behind the edge to .012" because of the bevel moving up the blade. With the ~12 degree apex bevel though, the true bte thickness is .003"-.004". Makes me curious if there's a more easily universal way to quantify cross section. I was confused by your talk of .001" and .002" bte, but now I see. Might be a good use for a sharpie before the micro bevel, as a differentiation to the secondary or tertiary that most would measure at.

On a separate note, in production do you do the majority of your grinding flat and then add the convex at the end?

You've recommended wool felt for backer to me in the past , have you tried leather before? How thick is your felt?

I checked my knife and I think the spots that rolled the worst were the same ones that had rolled previously. I ground down the rolls from the side before I ground back into the bevel, so those spots were left slightly thinner. It's ~.005 bte at 10 degrees with a barely perceptible micro bevel of ~16 degrees, .010" at ~.125-.08 up the edge. I hadn't checked my sharpening geometry recently and it looks like I let it creep up to much. Can't say I'm surprised about the ripples at this point.

I re-profiled my edc by taking the shoulder off at ~6 degrees. It went from .010" behind the edge to .012" because of the bevel moving up the blade. With the ~12 degree apex bevel though, the true bte thickness is .003"-.004". Makes me curious if there's a more easily universal way to quantify cross section. I was confused by your talk of .001" and .002" bte, but now I see. Might be a good use for a sharpie before the micro bevel, as a differentiation to the secondary or tertiary that most would measure at.

On a separate note, in production do you do the majority of your grinding flat and then add the convex at the end?

You've recommended wool felt for backer to me in the past , have you tried leather before? How thick is your felt?

|

Re: What can AEB-L handle in geometry February 15, 2022 03:18AM |

Admin Registered: 2 years ago Posts: 147 |

yes. i grind the main bevels 90% + flat. once the main grind is done and the edge is about 1mm or less thick, i typically move onto a 120grit ceramic belt with felt backing and use that to make a very fine convex.

without a backing, slack belts want to take the easiest path, so round the spine and apex, but dont get into the body well.. so you want that firm giving backing so you can press in a little and control the location of the curvature.

i tried a number of different backings including leather. leather isn't good for me with wet grinding. the water effects it. the heat effects it. you end up with a hard burnt compressed piece of leather not much better than wood and out of shape.

the felt i used was roughly 1/4" and would retain shape well. it would definately compress as on bigger blades i would be pushing in very hard to remove a lot of stock. but even compressed down, the felt is offering a soft backing which removes chatter and produces finer grind lines and ability to contour

in regards to BTE.. the value only has meaning if you are talking about a blade with a single grind and a single edge bevel. as the lessening and thickening of this value by nature of either edge angle, or profile angle is distinctly comparable with other things. the moment you start faceting or convexing it becomes a less useful value, which is why i tend to talk cross-sections. how thick is the blade at 0.005 from the edge, 0.010 , 0.020, 0.050" this is the same way you would plot a mountain in a 2d chart to get a representation of it so for me, its more about what is the maximum angle (the apex, and how often and how quickly that angle is reduced to form the shape of the knife)

without a backing, slack belts want to take the easiest path, so round the spine and apex, but dont get into the body well.. so you want that firm giving backing so you can press in a little and control the location of the curvature.

i tried a number of different backings including leather. leather isn't good for me with wet grinding. the water effects it. the heat effects it. you end up with a hard burnt compressed piece of leather not much better than wood and out of shape.

the felt i used was roughly 1/4" and would retain shape well. it would definately compress as on bigger blades i would be pushing in very hard to remove a lot of stock. but even compressed down, the felt is offering a soft backing which removes chatter and produces finer grind lines and ability to contour

in regards to BTE.. the value only has meaning if you are talking about a blade with a single grind and a single edge bevel. as the lessening and thickening of this value by nature of either edge angle, or profile angle is distinctly comparable with other things. the moment you start faceting or convexing it becomes a less useful value, which is why i tend to talk cross-sections. how thick is the blade at 0.005 from the edge, 0.010 , 0.020, 0.050" this is the same way you would plot a mountain in a 2d chart to get a representation of it so for me, its more about what is the maximum angle (the apex, and how often and how quickly that angle is reduced to form the shape of the knife)

|

Re: What can AEB-L handle in geometry February 16, 2022 06:52AM |

Admin Registered: 2 years ago Posts: 499 |

cKc, sal:

Before I fully understood how to sharpen, I put a 3-beveled edge on my Benchmade 13402 HD Pika G10 knife with my GATCO Edgemate fixed angle system. At the time I thought the edge bevel being sharpened was what I now know is a micro-bevel. I didn't think the stone touched the edge bevel until I did what I am talking about here. I was trying to get an 'Appleseed' grind, because of the 1970's ere Buck 118 Personal that I rescued from a pawn shop had that edge. It was super sharp, and still is one of my sharpest knives. That made me think that was the best way to have an edge on a knife, which led me to Cliff and Kyley and the old forum. So I used 3 different angle slots on the GATCO Edgemate. I liked that edge, the way it looked. It was like an enlarged version of the razor 3-bevel edge Kyley showed. I think the 3-bevel razor edge is like a mini-relief grind, followed by the next bevel, which is a little larger in angle, and then micro-beveled, most likely to remove the burr as well as increasing edge durability. Sal, an easy way to take a look at this 3-bevel edge is to get a 10-pack of Feather Brand Double Edged Razor Blades. These are reportedly some of the sharpest production edges to be found, the Straight Razor guys hold them in high esteem. I have a few packs myself as a benchmark of the sharpest I try to attain. I even have a video with one of those blades doing the HHT.

Before I fully understood how to sharpen, I put a 3-beveled edge on my Benchmade 13402 HD Pika G10 knife with my GATCO Edgemate fixed angle system. At the time I thought the edge bevel being sharpened was what I now know is a micro-bevel. I didn't think the stone touched the edge bevel until I did what I am talking about here. I was trying to get an 'Appleseed' grind, because of the 1970's ere Buck 118 Personal that I rescued from a pawn shop had that edge. It was super sharp, and still is one of my sharpest knives. That made me think that was the best way to have an edge on a knife, which led me to Cliff and Kyley and the old forum. So I used 3 different angle slots on the GATCO Edgemate. I liked that edge, the way it looked. It was like an enlarged version of the razor 3-bevel edge Kyley showed. I think the 3-bevel razor edge is like a mini-relief grind, followed by the next bevel, which is a little larger in angle, and then micro-beveled, most likely to remove the burr as well as increasing edge durability. Sal, an easy way to take a look at this 3-bevel edge is to get a 10-pack of Feather Brand Double Edged Razor Blades. These are reportedly some of the sharpest production edges to be found, the Straight Razor guys hold them in high esteem. I have a few packs myself as a benchmark of the sharpest I try to attain. I even have a video with one of those blades doing the HHT.

|

Re: What can AEB-L handle in geometry February 22, 2022 04:05AM |

Registered: 2 years ago Posts: 43 |

Sorry, only registered users may post in this forum.